|

|

|

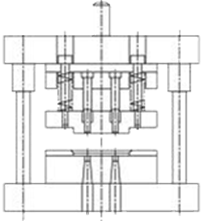

CE TOOLING DIE SET SETUP & MAINTENANCE |

|

SET UP PERSONS SHOULD KNOW FOLLOWING INFORMATIN ABUT PRESS & DIE.

Customer machine specifications: Open Height :_________ (Distance from bed to striker pad when stoke is in its up most position.) Shut Height : ________ (Distance from bed to striker pad when stroke is in its down/lowest stroke position.) Stroke Adjustment Available:_______ DIE SET Specifications: Zero Penetration Height:______ (Distance from bottom of die to top of die wear cutting edges sits .02”/.5mm from engagement.)

With this information, set up person can calculate size of riser blocks that die may need to be placed on. _ top and position of his stroke adjustment with intent for initial stroke of press to equal zero penetration Height of die. Then small adjustments can be made to achieve a 1-3mm entry of cutting. Dies that also form may require detailed stroke adjustment to spank/bottom out on material. |

|

Rough Set Up Guide for Die Sets: This assumes operator has already adjusted machine for the dies Zero Penetration Height. 1st Slide die set into press. Stroke of press should be set for Zero Penetration.

2nd Center to press and jog stroke onto Punch Chuck. Lift up on upper die when locking Chuck. Lower die plate should only be lightly secured to table. You want lower die to be able to skid and center itself in next step.. Never stroke press without material, especially during set up.

3rd. A Die Set will self-align to itself, but cannot always count n press stoking exactly perpendicular to die. What works great for aligning upper & lower die is to laying polyurethane sheets of thickness equal the dies per side clearance. Trivia: tool makers use to use ladies nylons. During the initial entry of cutting edges, the polyurethane material is protecting the cutting edges of die. When cutting edges squeeze the polyurethane material pressure is placed on cutting edges and die will naturally want to move to least resistance which means it self-centers. While press is jogged to down position and penetration into the die 1-3mm, tighten-secure lower die. If die also forms, set for minimal 1mm then test punch parts to set adjustment.

Quality dies will have REST PIN STOP. A REST PIN STOP is any method built into the die set to protect die when it is removed or being installed into press. It stops the free weight of upper unit from sliding down onto the lower unit and dulling the cutting edges. Never stroke die to depth that allows REST PIN STOP to bottom out.

|