|

Punch is made for a specific material thickness

|

|

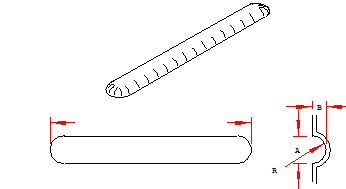

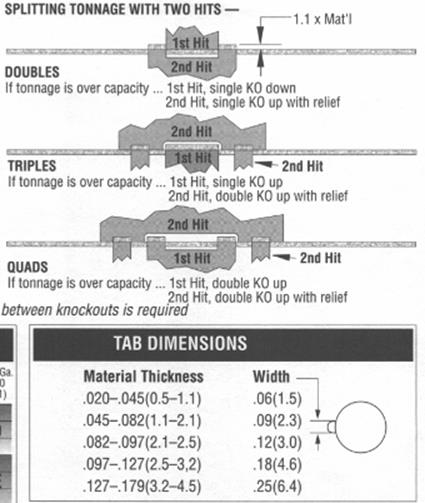

PROGRESSIVE STIFFENING RIB |

|

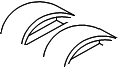

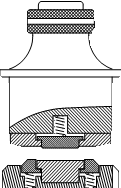

ELECTRICAL KNOCK OUT TOOLS |

|

E.K.O. QUAD (4) |

|

E.K.O TRIPLE (3) |

|

E.K.O. DOUBLE (2) |

|

E.K.O. SINGLE (1) |

|

Tonnage Requirements: Up to 3/4 of press capacity may be safely used. Use the below to calculate tonnage required for your knockout size and material. (ref. Page 7 for Ton-Per Sq. Inch) Perimeter or 3.14XØ X Mat’l thickness X Mat’l Ton-Per-Sq.Inch MS=25(22.5mm) AL=9.5-14(8-12,6mm) SST=50(45mm) Example: 1” Pipe=1.375 actual size, in 12ga. Galvanized/mild steel 3.14 X 1.375 X .105 X 25=11.33 English tons. |

|

RETURN TO FORMS DIRECTORY |

|

NEXT PAGE |

|

|

|

CE TOOLING ELECTRICAL KNOCK OUT |

|

Standard |

“A” |

“B” |

“R” |

|

Size |

3/8 |

3/16 |

3/16 |

|

Con-duit |

Actual Size |

Con-duit |

Actual Size |

|

1/2 |

.875 |

1½ |

2.000 |

|

3/4 |

1.125 |

2” |

2.500 |

|

1” |

1.375 |

2½ |

3.000 |

|

1¼ |

1.750 |

3” |

3.625 |

|

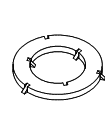

E.K.O. TAB LOCATION “Common Use Chart” |

||||

|

Actual Size Diameter |

SINGLE E.K.O. |

DOUBLE E.K.O. |

||

|

Lower |

Upper |

Lower |

Upper |

|

|

0-.249 * (0-6,3mm *) |

|

|

|

|

|

.250-.313 (6,4-8,0mm) |

|

|

|

|

|

.3140-1.374 (8,0-34,9mm) |

|

|

|

|

|

1.374 –Max.(34,9mm–Max.) |

|

|

|

|

|

* Must have tab on lower & Upper if thicker than 16 gauge. Thinner materials only need tab on Upper. |

||||