|

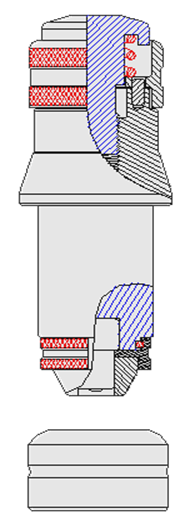

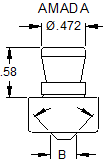

Sta.A 1/2” Form Down Coin can be order in standard style assembly. Penetration adjustment is accomplished with Side Lock Punch Head |

|

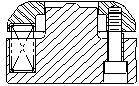

COINING (Counter Sink) TOOL

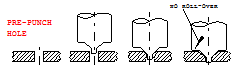

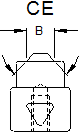

A coined hole is used to enable a flat head screw or rivet to fit flat or below the surface of the sheet. As the below diagram shows, CE.Tooling recommends use of a pre-punched hole before the actual coining is performed. This achieves the highest quality coined hole, with no roll-over, minimal burr, and excellent tool life.

If a one operation pierced and form is Chosen, be advised that the hole quality and tool life will be greatly reduced. Reason: The metal being coined has no were to go but to bulge on the top of sheet (roll over), against the pilot tip and pushes below the sheet leaving a large burr. This binding of the pilot tip by the material causes rapid galling which if not constantly cleaned off can cause the pilot tip to be snapped off during the stripping cycle of the stroke.

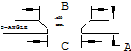

FORM DOWN FORM UP

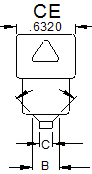

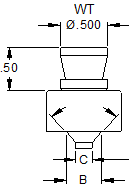

Note: Minimum C = B-(2((Angle/2)TAN x mat.thickness)) Pre-Pierce Hole Formula. (Note, this will estimate to large size) after test hits, size may be reduced slightly to achieve best cosmetic results on material type and thickness being punched. Pre-Pierce Hole = C + ((B-C) / 2) Form Depth > 80% of Material Thickness not suggested.

|

|

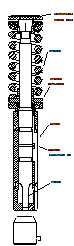

Form Inserts for CE, WT & Amada Style Holders |

|

RETURN TO FORMS DIRECTORY |

|

NEXT PAGE |

|

ELECTRICAL KNOCK OUT TOOLS |

|

|

|

CE TOOLING Coining (Counter Sink) • Extrusions |